Cement Drying Time: Discover How Long It Takes for Cement to Dry!

Cement Drying Time: Understanding the Basics

When working with cement, understanding the **cement drying time** is crucial for any construction project. The process isn’t as straightforward as one might think. Various factors significantly impact how long **cement** takes to dry, including the complexity of the **hydration process in cement**, moisture content, and environmental conditions. In general, it is essential to know that cement doesn’t fully cure just based on drying. Proper **curing cement duration** is vital for achieving the desired strength and durability.

The Hydration and Drying Process in Cement

The **hydration process in cement** is pivotal for developing its compressive strength. Once mixed with water, a chemical reaction begins, involving compounds forming crystals that will solidify the mixture. The initial phase of **typical cement drying** might seem quick, especially within the first few days. Still, it may take weeks or even months to reach full strength. During this time, maintaining adequate moisture levels is key to reducing issues such as cracking or shrinkage. Curing methods, such as water spraying or utilizing curing compounds, are essential for prolonging moisture retention in the cement.

Factors Affecting Cement Drying Time

Several environmental and material factors affect the **cement setting time** and drying duration. One major factor is ambient temperature, as it can dramatically influence evaporation rates and overall hydration. Higher temperatures can accelerate initial hydration but may lead to **inadequate curing issues**, while lower temperatures slow down the reaction significantly. Likewise, the **thickness of the cement layer** also plays a crucial role; thicker layers will take longer to dry completely. Always consider variables like ambient humidity and wind exposure in estimating the drying time accurately.

Best Practices for Curing Cement

Implementing **best practices for curing cement** can significantly enhance its strength and longevity. Techniques to improve drying include using appropriate **cement mix ratios** and additives designed to promote faster curing. Additionally, use plastic sheeting to trap moisture, ensuring optimal **curing conditions for cement**. For outdoor projects, consider environmental factors, such as prevailing winds that could lead to quicker drying and potential surface cracking. By observing these practices, not only does one enhance the **cement bonding quality**, but also leads to heightened structural integrity for any construction.

Types of Cement: Which One is Right for Your Project?

The choice of **types of cement available** is critical for addressing specific project requirements. Different formulations, such as **high-performance cement options**, exhibit varying properties regarding setting and curing. **Quick-setting cement**, for instance, is great for urgent repairs but offers limited working time. Thus, evaluate your project needs carefully, including desired **compressive strength of cement** and conditions that will affect the curing duration.

Understanding Various Cement Mix Ratios

Utilizing the correct **cement mix ratios** can lead to significant improvements in the properties of the cured material. A mix high in cement and low in aggregates might set quickly but can lead to durability issues. Conversely, too much aggregate can result in weak bonding and inadequate **concrete hardening periods**. Typical ratios depend on the intended application, whether it’s for structure, pavement, or artistic finishes. Following proper mixing guidelines remains crucial to the overall outcome of your project.

Cement Applications in Construction

Each **cement application in construction** may require unique formulations to ensure optimal results. Considerations such as moisture retention and ecological impacts during the **cement dry-out techniques** should always be top of mind. For instance, utilizing **environmentally friendly mixes** not only contributes towards sustainability efforts but can also optimize the efficiency of the drying process. Understanding your project’s goals will guide you to select the right kind of **cement-based materials**, enhancing longevity and overall performance.

Common Issues and Solutions in Cement Drying

<pDespite best efforts, challenges may arise during the **cement drying process**. Recognizing potential problems early can save time and resources. Common issues—such as inadequate curing leading to weaknesses—can often be avoided by implementing correct **curing duration recommendations** and ensuring proper site conditions during the drying period.

Environmental Factors and Their Impact on Cement Drying

Be aware of how **environmental factors in cement drying** can alter drying thresholds. Wind, humidity, and temperature can all impact the **drying conditions for cement**. For instance, high winds can hasten evaporation, causing the surface to dry too quickly—leading to potential cracking. Conversely, too much humidity may slow down the process considerably, extending the original timeline for project completion. It’s vital to monitor these factors continually, adjusting strategies as needed to ensure the desired outcome.

Post-Curing Treatments for Cement

Implementing effective **post-curing treatments for cement** optimizes its durability significantly. After the specified curing period, utilizing treatments such as surface sealers protects against moisture loss while also reducing shrinkage. These therapies play a crucial role in achieving long-term **cement longevity in exposed environments** and enhancing resistance to environmental stresses, fortifying structures against potential damage over time.

Conclusion: Mastering Cement Drying Time

In construction, understanding and optimizing **cement drying time** is crucial both for project success and the durability of structures. By recognizing the factors affecting this process, including temperature, moisture content, and mix ratios, engineers and builders can implement best practices tailored to their specific needs. By focusing on factors such as proper curing methods and preparation, construction professionals will enhance the quality of their cement work, ultimately leading to stronger, longer-lasting projects.

FAQ

1. How can I speed up the curing process of cement?

To speed up the curing process, consider using **quick-setting cement** or additives designed for faster hydration. Additionally, maintaining optimal temperature control during the curing phase can improve drying rates. Finally, ensure you cover the cement adequately to retain moisture without interfering with the curing process, effectively enhancing strength and performance.

2. Can I use plastic sheeting to cure cement in rainy weather?

Using plastic sheeting for **curing cement in rainy weather** can be beneficial but should be done with care. The plastic helps to retain moisture while preventing excess water from directly impacting the surface. However, ensure proper ventilation to avoid trapping moisture that could lead to weakening or other **inadequate curing issues**. Managing the moisture levels is key.

3. What is the average drying time for cement?

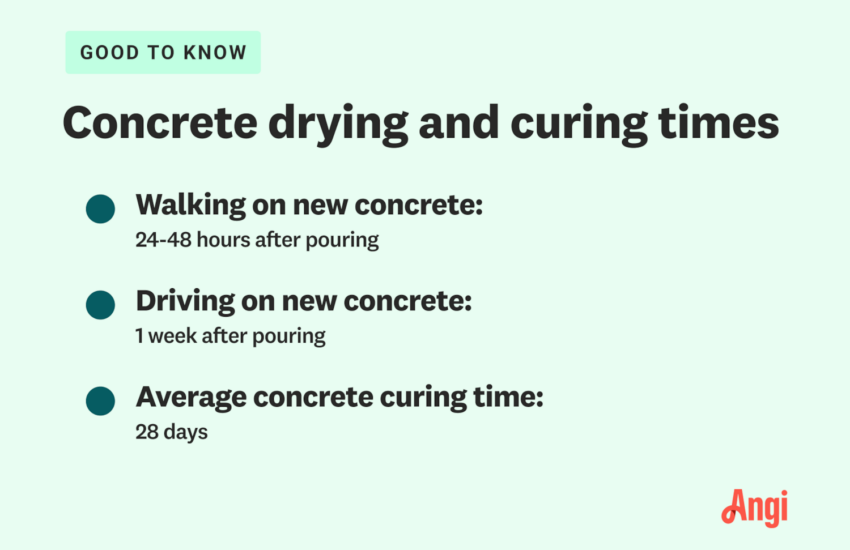

The average **cement drying time** can vary based on several factors, including temperature and humidity. However, a general guideline is that cement reaches initial set in about 24-48 hours, while significant strength is typically achieved after 28 days. Always consider the specific conditions and material usage for a more accurate estimate.

4. How does ambient temperature affect cement drying?

**Ambient temperature impact** on cement drying is substantial. Higher temperatures can accelerate curing time but may result in a higher chance of cracking. On the other hand, low temperatures slow the hydration process, extending drying time. Thus, maintaining a balanced temperature during the curing period is vital for achieving optimal results.

5. Why is curing important for cement structures?

**Curing** is crucial for cement structures because it ensures that the cement gains strength and durability over time. Proper curing facilitates optimal **hydration stages**, leading to low shrinkage, minimal cracking, and enhanced compressive strength. Investing time and care into the curing process ultimately guarantees better performance and longevity of concrete structures.